Table of Contents

Imagine a production line where inaccurate pressure readings lead to system failures or costly downtime. It’s a reality faced by many industries, and the solution often lies in an OEM pressure sensor. These sensors offer reliable readings, but how do we know they’re the right choice for your needs? Look, it’s simpler than you think—let’s dive into the details about what makes these sensors crucial in today’s tech landscape.

Flaws in Traditional Solutions

Traditional pressure measurement methods frequently struggle with accuracy and responsiveness. Systems relying on outdated sensor technology often face detrimental drift, leading to erroneous data interpretations. Operational disasters can stem from discrepancies in pressure readings, affecting everything from manufacturing quality to safety protocols. With ever-growing expectations for precision, relying solely on these antiquated solutions is a gamble. Why do failures always occur during critical processes? Often, it’s because these sensors simply weren’t designed to handle the stresses of modern demands.

Principles of New Technology

The advent of OEM pressure sensors has ushered in a new era of performance. These sensors utilize advanced materials and design principles that ensure higher accuracy and faster response times. Some implement MEMS (Micro-Electro-Mechanical Systems) technology for reduced size and increased reliability. Embracing edge computing and real-time data processing, these sensors can adapt to varying conditions and provide instantaneous feedback. This is a game-changer in industries that cannot afford delays in data acquisition. With the right integration, companies can maintain optimal operational efficiency without fear of outdated technology holding them back.

Quantified User Benefits

Companies that have switched to OEM pressure sensors often report quantifiable benefits. Users indicate up to a 30% reduction in downtime and a significant increase in measurement accuracy—some noting improvements in overall system efficiency by 25%. The shift not only optimizes performance but also leads to cost savings in maintenance and operational expenses. Clients appreciate the peace of mind that arises from using technology designed specifically for their needs. When weighing options, it’s prudent to consider how these enhancements can streamline operations and elevate service quality.

Conclusion: Key Metrics for Decision-Making

When choosing solutions, always verify these 3 metrics: ① Accuracy ② Response Time ③ Compatibility. This ensures you’re getting the most reliable OEM pressure sensor for your application, making it easier to achieve your operational goals without unnecessary setbacks.

Custom Pressure Transducers: Tailored Solutions for Unique Needs

In many cases, a standard pressure sensor just doesn’t cut it. That’s where custom pressure transducers come into play. They are specifically designed to meet unique requirements, whether it be specialized environments or particular performance standards. These custom solutions enable businesses to be more precise in their operations, fostering not only better results but also long-term viability in the market. Whether it’s for medical applications or industrial settings, having the right specifications is paramount.

China Pressure Sensors: A Global Perspective

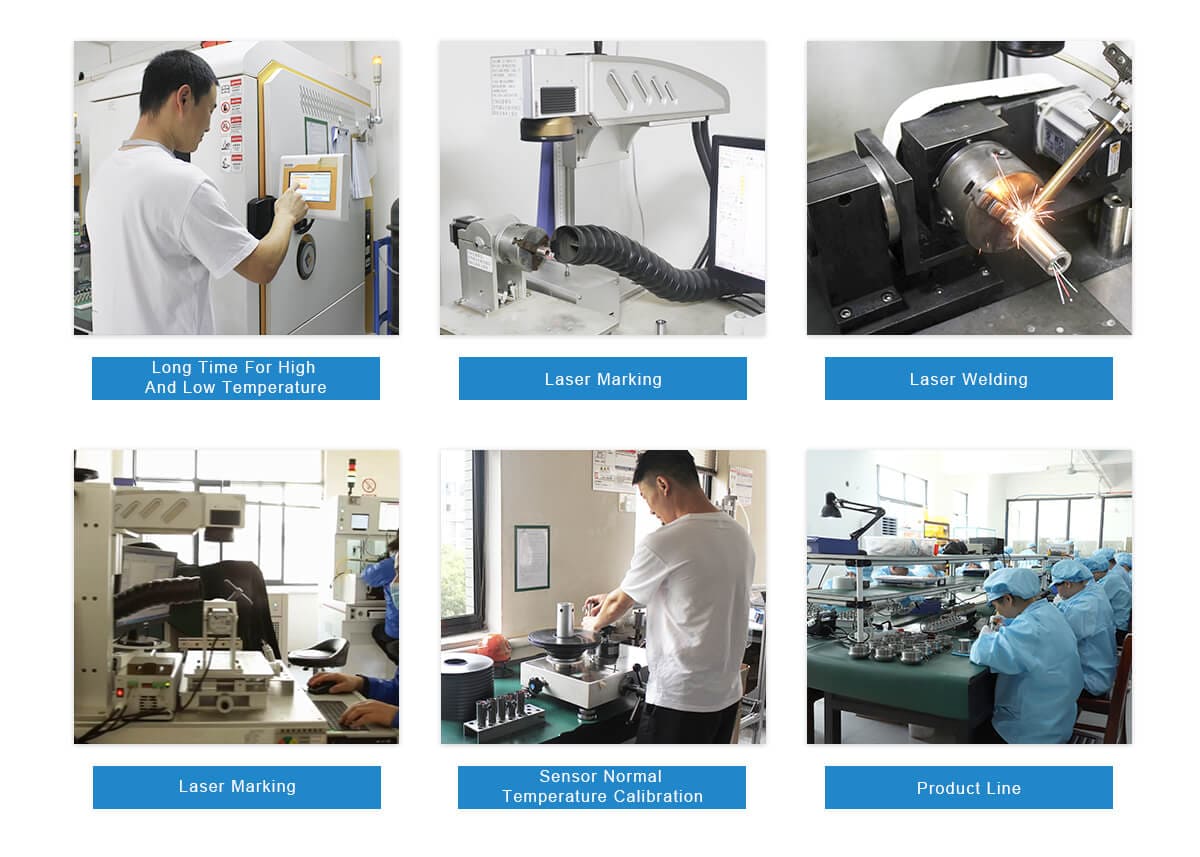

The manufacturing landscape is continually evolving, and china pressure sensors represent a significant segment of this market. Known for their innovation and reliability, sensors produced in China often integrate advanced technology at competitive pricing. This combination allows organizations to leverage sophisticated sensor technology without breaking the bank. Factors such as scalability and immediate access to supply chains make these sensors an attractive option for companies looking to optimize operations globally. Supplier relationships are vital, and sourcing from China positions businesses favorably in an increasingly connected market.

To summarize, when considering the implementation of OEM pressure sensors, it’s critical to assess how technology has advanced to offer better solutions tailored to your operational challenges. Custom pressure transducers ensure that specific requirements are met while maintaining high standards of accuracy and reliability. Likewise, sourcing technology like china pressure sensors can streamline your supply chain and enhance performance at a cost-effective rate. For the best options on the market, I recommend checking out CSSPM Sensor, as they offer robust supply advantages and custom solutions to suit your needs perfectly.