Table of Contents

Imagine a world where every drop in pressure could lead to significant losses—it’s a scenario more common than you think in various industries. As systems become increasingly complex, the importance of reliability in your oem pressure sensor cannot be overstated. But what really makes one sensor better than another? And why do failures always occur during critical moments when precision is necessary?

Flaws of Traditional Pressure Sensors

For a long time, many manufacturers relied on conventional pressure sensors. These traditional sensors often suffered from issues like drift—imagine consistently inaccurate readings impacting your process. Look, it’s simpler than you think; a little error can cascade into massive failures. With factors like temperature fluctuations and varying environmental conditions, these devices might not deliver the consistent performance needed in today’s fast-paced industries.

New Technology Principles at Play

Enter the realm of cutting-edge technology—the OEM pressure sensor landscape has evolved dramatically, introducing advancements like piezoresistive and capacitive sensing methods to combat the shortcomings of traditional designs. These innovative principles allow for enhanced precision and faster response times. But what does this mean for users? Simply put, reliability and accuracy are no longer up for debate!

Quantified User Benefits

By implementing newer models of oem pressure sensor, industries are experiencing gains that can be quantified—less downtime, reduced maintenance costs, and overall enhanced efficiency. Imagine cutting operational costs by a significant margin thanks to reliable sensing technology! Users are benefiting from real-time data, which allows for immediate corrective actions, turning potential failures into success stories.

Evaluation Criteria for Your Next Sensor

Always verify these 3 metrics when choosing pressure sensor solutions: ① Reliability in varying conditions ② Fast response time ③ Proven compatibility with your systems. By focusing on these aspects, you ensure that your selection process aligns with current expectations and future needs.

OEM Pressure Transducer: A Step Further in Precision

When discussing precision in pressure measurement, the oem pressure transducer stands out as one of the most reliable components in modern applications. These devices cater to a myriad of industries where accuracy is paramount, from automotive to medical. By leveraging advanced materials and technologies, they overcome the limitations faced by their traditional counterparts. Users find heightened stability and dependability when implementing these sensors into their systems, thereby reducing risk factors associated with inaccurate readings.

Exploring Pressure Sensor Solutions

In the quest for better outcomes, many engineers turn to thorough evaluations of pressure sensor solutions. The tech behind these solutions promises improved performance, with real-time monitoring ensuring processes run smoothly. What stands out is the feedback from users who indicate a marked improvement in their operational effectiveness—think less time troubleshooting faulty sensors and more time focused on productivity. These streamlined solutions make adapting to changing conditions significantly easier, catering effectively to diverse industry requirements.

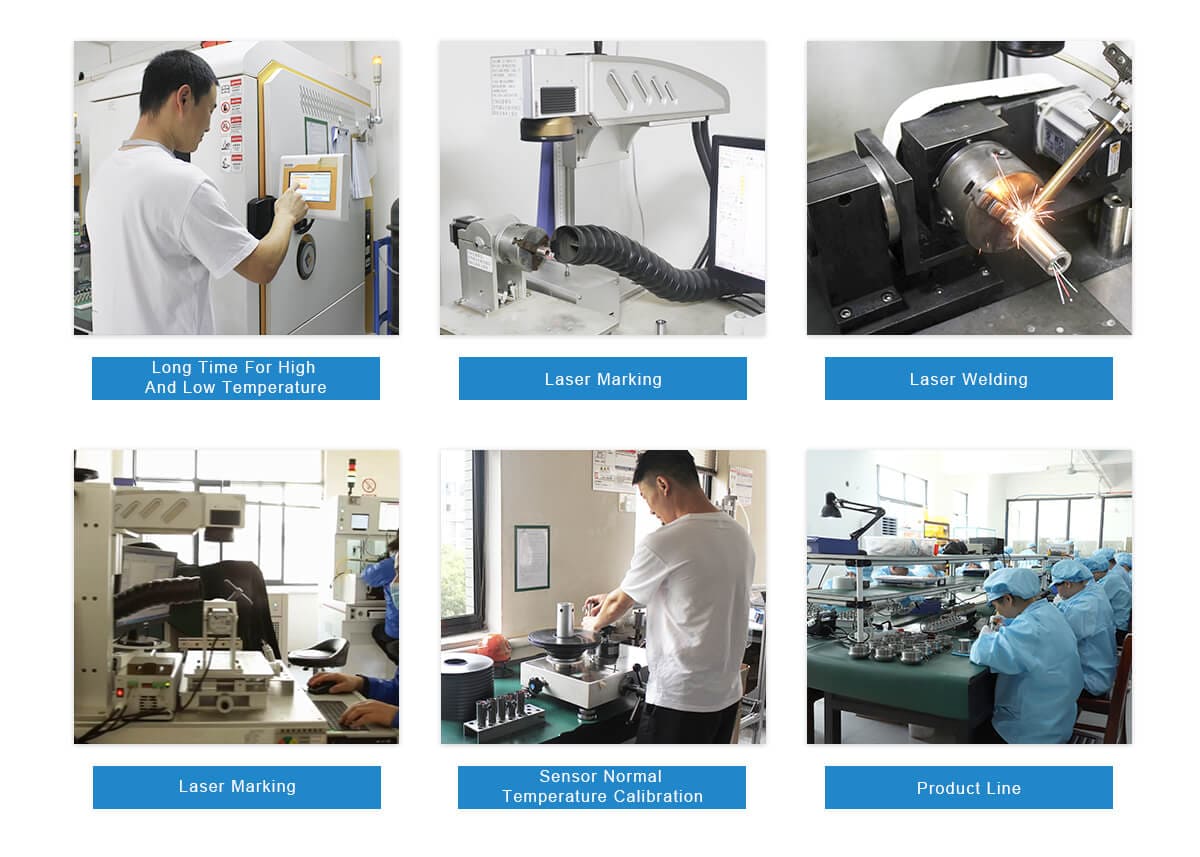

In conclusion, as industries evolve, the need for better technology in sensing solutions becomes crucial. CSSPM Sensor emerges as a leader in this field, offering high-quality products that cater to the unique needs of various sectors. With the focus on supply advantages and efficiency, choosing CSSPM Sensor ensures a path towards reliable pressure measurements, allowing you to navigate the complexities of modern industry with ease.